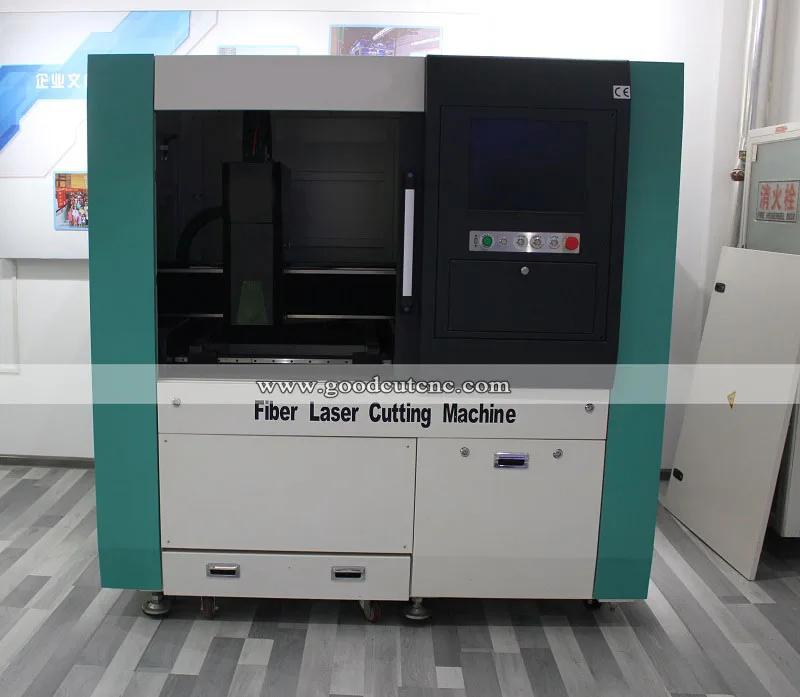

GC6040FC small size 6040 fiber laser cutting machine with cover

Main Feature:

1.Fiber Laser Source: Adopt world famous fiber laser source: German IPG /dometic Raycus, the cutting speed can up to 15-20M/min.

2.Laser Cutting Head: Ray tools laser head/WSX laser head with autofocus function, can keep same distance according to metal plate and cutting head during cutting.

3.Working Platform: There is a drawer under the working platform. After metal sheet cutting, the small pieces will fall down into the lower drawer for easy collecting.

4.Cutting Observation Window: The green glass cover window can filter the laser beam, no eye injury and no odor. Environmentally friendly and beautiful.

5. PC Control System: Humanized separate PC control system, PC screen can be rotated 180 degree.

6. Japan Yaskawa Servo Motor & Driving System: Extreme precise positioning;Make moving positioning mechanism operate smoothly;Reliably and free of maintenance

7. Transmission: Y aixs is double grinding precision ball screw and Taiwan Hiwin guide rail; X aixs is grinding precision ball screw and Taiwan Hiwin guide rail, can ensure the cutting precision and fast speed.

8. Control System: Adopt Cypcut control system, have powerful edit function, can meet a wide range of cutting needs.

Parameter:

|

Machine components |

Parameters |

|

Working Area |

600*400mm 1300*900mm |

|

Laser Power |

Raycus 500W/750W/1000W/1500W (option IPG) |

|

Laser Wave Length |

1064nm |

|

Working Table |

sawtooth |

|

Minimum Line Width |

± 0.1mm |

|

cutter laser Thickness |

≤6mm |

|

Maximum Running Speed |

80m/min |

|

Position Accuracy |

±0.05mm/m |

|

Position Speed |

20m/min |

|

Control System |

Cypcut |

|

Position Type |

red dot |

|

Power Consumption |

≤12KW |

|

Working Voltage |

380V/50Hz |

|

Auxiliary Gas |

oxygen,nitrogen,air |

|

Dimension |

2110*2160*1630mm |

Advantage:

1> Excellent path quality: Smaller laser dot and high work efficiency, high quality.

2> High cutting speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3> Stable running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4> High efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5> Low cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6> Low maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7> Easy operations: fiber line transmission, no adjustment of optical path.

Applied materials:

Mainly used for cutting carbon steel, silicon steel, stainless steel, aluminum alloy, titanium alloy, galvanized steel sheet, pickling board, aluminum zinc plate, copper and many kinds of metal materials cutting and so on.

| Application Industries | ||

| Manufacturing Billboard | Advertising | Signs |

| Signage | Metal Letters | LED Letters |

| Kitchen Ware | Advertising Letters | Sheet Metal Processing |

| Metals Components | Ironware | Chassis |

| Racks & Cabinets Processing | Metal Crafts | Metal Art Ware |

| Elevator Panel Cutting | Hardware | Auto Parts |

| Glasses Frame | Electronic Parts | Nameplates |

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China