Causes of edge burning and slag hanging of sheet metal parts processed by laser cutting machine:

Laser cutting of sheet metal will produce a lot of heat. Under normal circumstances, the heat generated by cutting will spread along the cutting seam to the processed sheet metal to get sufficient cooling.

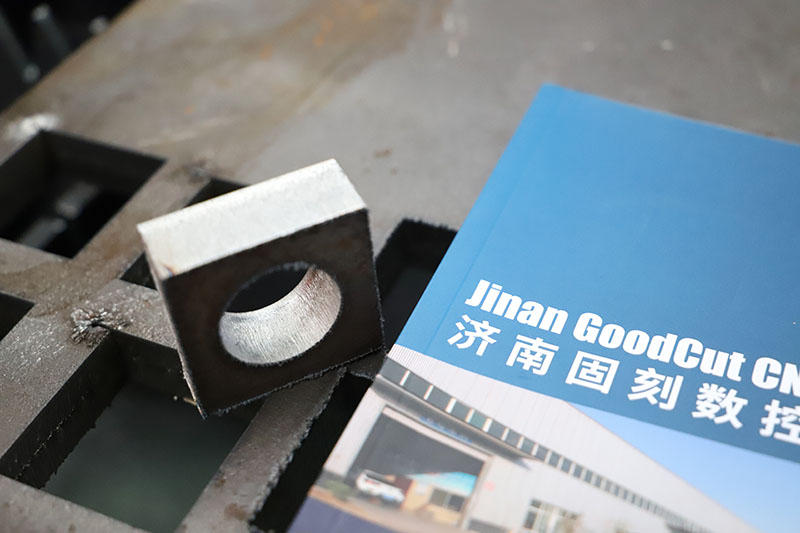

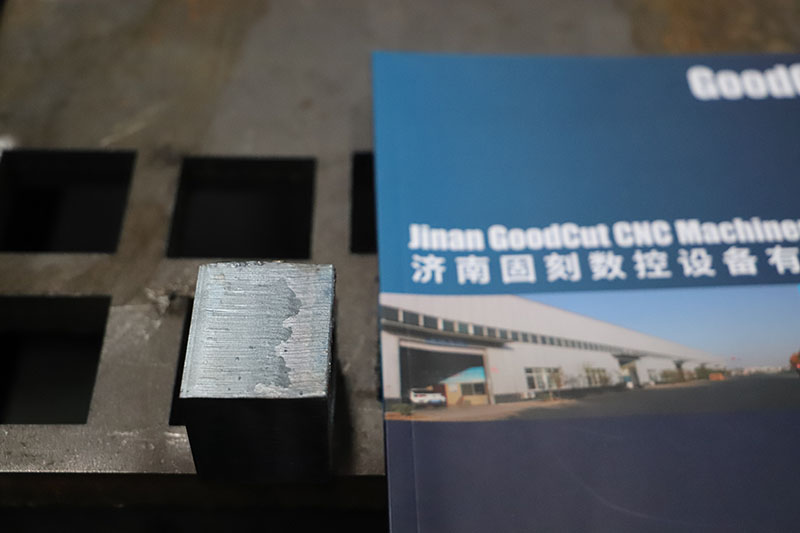

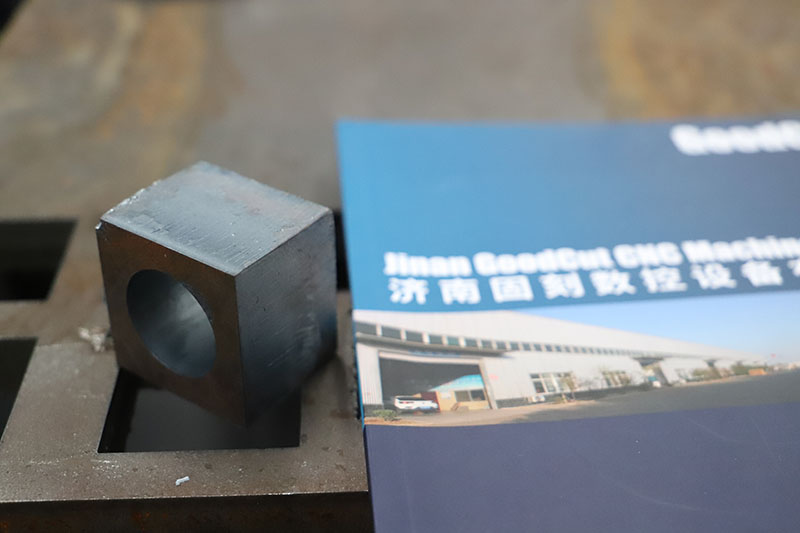

Especially in the processing of metal laser cutting machine, the outer side of the hole can be fully cooled, but the inner part of the hole is too small because of the heat diffusible space, the heat energy is too concentrated, resulting in overburning, slag hanging and so on. In addition, in the thick plate cutting, the molten metal and heat accumulated on the surface of the material during the perforation will cause the auxiliary air flow to be disordered and the heat input to be excessive, which will lead to overburning.

How to solve the problem of edge burning and slag hanging?

Solution to overburning during laser cutting of carbon steel small holes: in carbon steel cutting with oxygen as auxiliary gas, the key to solve the problem lies in how to inhibit the generation of oxidation reaction heat, which can be cut with auxiliary oxygen during perforation and then switched to auxiliary air or nitrogen.

The pulse cutting conditions with low frequency and high peak output power can reduce the heat output and help to optimize the cutting conditions. Setting the conditions as single pulse laser beam, high peak output and low frequency can effectively reduce the accumulation of molten metal on the surface of the material and effectively inhibit the heat output.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China