Any equipment will have a corresponding loss during usage

To keep the high performance of equipment

A regularly equipment maintenance is needed

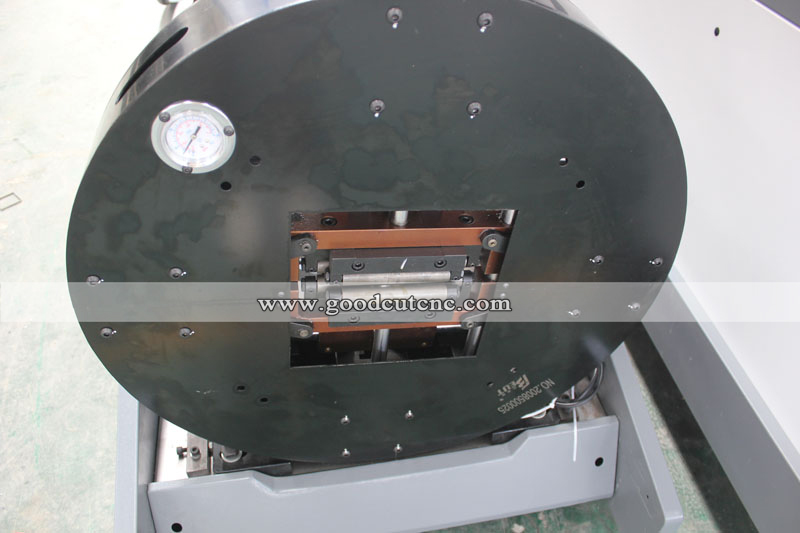

The chuck, as a most important part of the laser pipe cutting machine

Daily maintenance is crucial to keep the precision and performance of the machine

Here are some tips for chuck maintenance

1 Regularly Lubricate

Lubricant should be applied to the chuck regularly to ensure that the chuck can have a higher accuracy while moving. It should be noted that incorrect lubrication methods may cause the pneumatic chuck to not work normally at the low air pressure, weaken the clamping force, poor clamping accuracy, abnormal wear or jam, so we need to apply lubricating oil regularly and correctly.

2 Use molybdenum disulfide grease

Using molybdenum disulfide grease (black in color), inject the grease into the chuck nozzle until the grease overflows the jaw surface or the inner hole of the chuck. If the chuck is used at a high frequency for a long time, or a large amount of oxygen is used in the cutting process, more lubrication is required, and the frequency of lubrication must be increased according to the specific situation.

3 Special chuck for special tubes

Special workpieces or non-standard workpieces need to be clamped and processed with special chucks. The standard laser tube cutting chuck is suitable for symmetrical closed tubes. If you barely clamp irregular workpieces, the chuck will be abnormal; if the air supply pressure of the chuck is too high, the chuck will work under high pressure, which will reduce The service life of the chuck has problems such as excessive chuck clearance.

4 Clean regularly

After the machine has been used for a period of time, a high-pressure air gun needs to be used to deal with the dust and residue at the chuck itself and the slideway. It is recommended to clean the chuck jaws every 3-6 months to keep the surface clean and provide lubrication. Check all parts for cracks and wear, and replace them when they are severely worn.

5 Prevent the chuck from rusting

Rusting of the chuck will reduce the clamping force and fail to clamp the workpiece, which will seriously affect the production accuracy and efficiency. The use of anti-rust oil can prevent the exposed metal of the chuck from rusting.

By doing a proper job in the maintenance of the chuck to make the chuck more durable and the performance of the laser pipe cutting machine to be consistent, so as to better create wealth.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China