The laser welding computing device makes use of high-energy laser pulses to regionally warmth the fabric in a small area. The strength of the laser radiation diffuses to the interior of the cloth thru warmness conduction, and the cloth is melted to structure a precise molten pool.

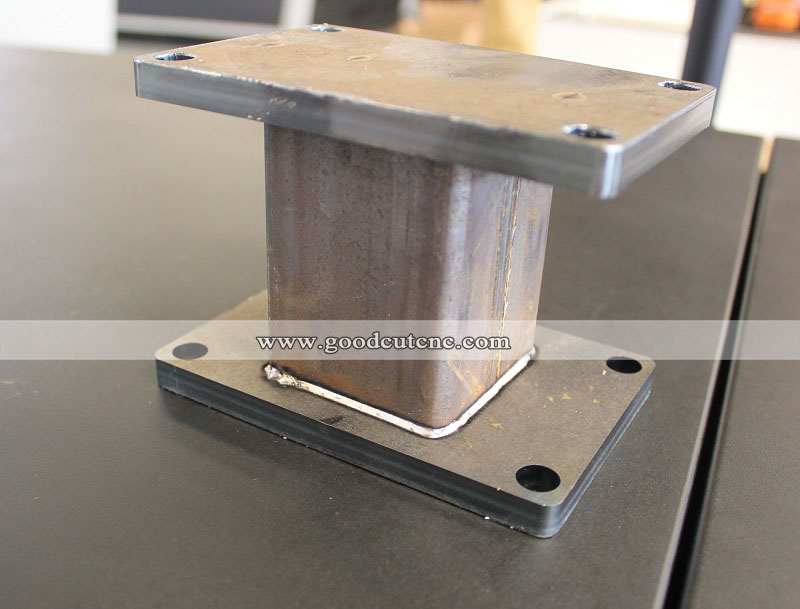

Laser welding desktop is a new kind of welding method, generally aimed at welding thin-walled substances and precision parts. It can comprehend spot welding, butt welding, lap welding, sealing welding, etc., with excessive component ratio, small weld width, and heat-affected quarter Small size, small deformation, quick welding speed, clean and lovely weld seam, no want for post-welding remedy or solely easy treatment, excessive first-rate weld seam, no porosity, specific control, small focal point spot, excessive positioning accuracy, handy to recognize automation.

At present, laser welding equipment has penetrated into our lives, and its applications are becoming more and more extensive, gradually replacing traditional welding methods. So, which industries are laser welding machines used in?

Laser welding machines are widely used in the sanitary industry: welding of water pipe joints, reducing joints, tees, valves, and showers. Glasses industry: precision welding of stainless steel, titanium alloy and other materials such as glasses buckle, outer frame and other positions. Hardware industry: welding of impellers, kettles, handles, etc., complex stampings and castings.

Laser welding machines are widely used in the automotive industry: engine cylinder head gasket, hydraulic tappet seal welding, spark plug welding, filter welding, etc. Medical industry: welding of medical appliances, stainless steel seals of medical appliances, and structural parts. Electronics industry: solid state relay sealing and welding, welding of connectors and connectors, welding of metal shells and structural parts such as mobile phones and MP3s. Welding of motor housing and wiring, fiber optic connector joints, etc. Household hardware, kitchen utensils and bathrooms, stainless steel door handles, electronic components, sensors, clocks, precision machinery, communications, handicrafts and other industries, automotive hydraulic tappets and other industries with high strength welding.

The advantages of laser welding machines are concentrated energy, no pollution, small solder joints, wide range of weldable materials, high applicability, high-efficiency and high-speed welding, etc. Products that require welds are welded with laser welding equipment, which not only has small welds, but also does not require solder. Products with high automation: Laser welding equipment can be manually programmed for welding, and the path is automatic.

It can weld inaccessible parts, implement non-contact long-distance welding, and has great sensitivity. It can be welded at room temperature or under special conditions, and the laser welding equipment is easy to install. For example, when the laser passes through the electromagnetic field, the beam will not deviate; the laser can weld in vacuum, air and certain gas environments, and can weld through glass or materials that are transparent to the beam.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China