1, First of all, what is a nesting system?

Nesting is a way to increase the utilization rate of materials on a limited material area, and reduce material waste. Which is a commonly used method in machining, shipbuilding, and other industries. By making full use of the materials, a company could reduce production resources hence save costs.

According to the size of the single piece required by the drawing, the required piece is divided from the material. A nesting system can help you optimize this process and help you achieve the utilization of raw materials in the shortest time. That is why the nesting system is widely needed in the manufacturing industry.

2. Why needing a nesting system?

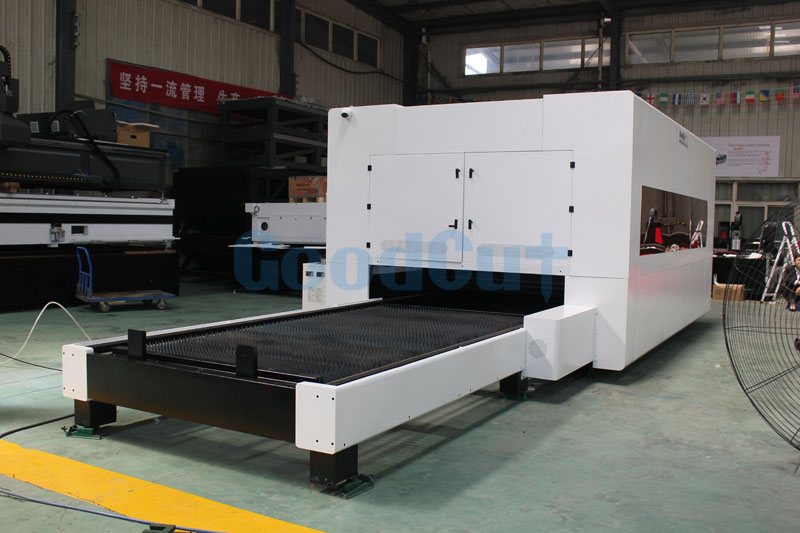

The realization of nesting by computer is a fast nesting method, which is to draw the board on the software according to the drawing size at a ratio of 1:1, and then use special software to process the DWG file of the board to generate the corresponding single-cutting program, and then Then these single cutting programs are arranged on the steel plate of fixed specifications through special software (used with the fiber cutting machine), and finally, a number cutting program is generated. Copy this number cutting program into the fiber cutting machine to automatically cut. The position of single-cut parts can be adjusted arbitrarily when typesetting on the steel plate, and it can also be rotated, which can improve the efficiency of material utilization.

The professional nesting software will do the overall nesting. The cutting workers only need to operate the CNC machine without adjustment. The entire nesting process is completed on the computer. Advanced nesting software and advanced cutting technology are used to improve the on-site cutting efficiency while ensuring that the utilization rate of the steel plate is 92%~94%.

For the pipe cutting machine, the nesting system is the guarantee of operation. All tube cutting machines of our company come with basic tubes-t (lite). This nesting system can achieve the nesting process of round, square, hexagon, oval and rectangular pipes. However, if you are dealing with more complex shaped tubes, such as angle, C beams and I beam. Then the tubes-t lite version is not enough for you. In that case, you will need a pro version of the tube nesting system.

3. Do I need a nesting system?

After understanding the nesting procedure and nesting system, it is time to consider whether you need to use nesting software for your fiber laser cutter.

Here are some key considering points.

1. Do I need to process special-shaped steel pipes?

For manufacturers who cut special-shaped steel pipes. The nesting system is a must. Otherwise, it is impossible to cut steel such as angle steel, channel steel, I-beam, etc. For those who deal with ordinary-shaped tubes, a nesting system would be a great plus, but not a must.

2. Do I need to cut a large number of parts with different shapes on a steel plate?

In general, a plate cutting machine doesn’t need a nesting system to operation, however, it can help you improve the utilization efficiency of steel plates and increase the cutting speed. So if you have the above needs, nesting software can help you reduce raw material consumption and improve production efficiency.

3. What is my productivity?

High-end nesting software is not free. So if you are simply cutting, and the above two conditions do not suit you, then you can consider not installing nesting software to help you save valuable budget at the beginning of your business. But you can rest assured that if you have related needs in the future, you can always contact us. We can help you install it remotely. After all, GoodCut strives to fulfill your needs.

Contact: Smile Ji

Wechat: 008618396857273

Whatsapp: 008618396857273

Tel: 008618396857273

Email: smileji@goodcutcnc.com

Add: 402 Jinxing Longsheng Building, High-tech district, Jinan City, Shandong Province, China